Energy management system

Power Studio SCADA is a unique Energy Management application that monitors and analyses the consumption of energy (electricity, water, gas, oil, etc.), Energy Performance Indicators and specific KPIs in real time for a any number of points in the factory.

“All for one, and one for all” is an old motto about dedication and loyalty that perfectly describes our Energy Management System (EnMS) and the savings it provides.

Now, instead of the Three Musketeers, we have an exceptional team of engineers at your disposal who will: analyze existing situation and customer needs, engineer an optimal technical solution, design optimal set of EnPIs and KPIs to follow, ensure short delivery and implementation period for EnMS hardware and software components, with an adequate and precisely-defined quote, without any hidden costs for maintenance and software updates.

One team – a solution for everything.

Expenses related to energy consumption take up the major part of the total production costs. Still, in most of the cases, these are not tracked together with the other production costs, rather they are tracked on a monthly basis, based on the electricity, water, and gas utility bills. That is the only reason why this type of expenses is considered as a constant, or, in other words, they are considered to be unmanageable or hardly variable.

We offer a different approach

Based on our extensive experience, we are aware one of the major obstacles for the wider application of rationalization is the inability to measure the production segment for which one is trying to reduce consumption. This is precisely the reason why the result of rationalization is often not visible in the consumption of the entire power station and it is impossible to single out that particular result and draw conclusions about its success.

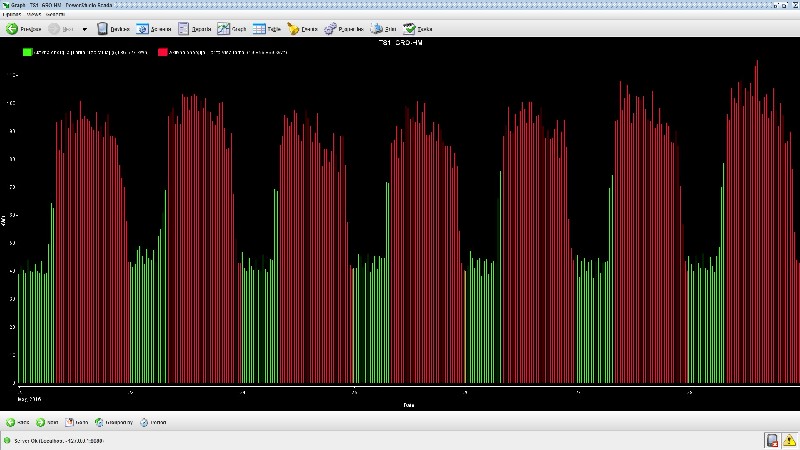

We implement economic and simple solutions which are tracking the consumption of energy (power, water, gas, oil, etc.) in real time for multiple points in the factory. This way, customer gets a unique tool with a high resolution both in time and space, which monitors the quantity of the consumed energy by the minute for each machine at the factory, per product, per unit!

Tool for finding hidden costs

By relying on our solutions, you’d have the right tools at hand that will assess the effects of implemented measures of rationalization, because the system is able to accurately measure the production segment to which the rationalization is applied, and compare the consumption and KPIs in old and new regime. Once the existing level of consumption of the energy is set, it is automatically monitored and you are warned if the consumption goes over the limit, in which case, the irrational mode is immediately identified. Such a tool is ideal for the implementation of ISO 50.001 standard in factories, as well as continuous improvement of energy-efficiency.

As the cherry on the cake of the entire project, there are automatically generated reports on consumption of energy, EnPIs and KPIs at the end of each day, week or month, as well as the reports on acquired data regarding the quality of voltage (voltage sags, interruptions, distortions, etc.).

References

Avalon Partners experts have implemented a large number of solutions in factories, office buildings and shopping malls. We have the necessary experience, knowledge, and the will to set up a system that you have always wanted to have in your facility but never had the necessary know-how to implement it adequately.

We guarantee that only top-notch sofware and energy experts will be working on your project, analyze the existing situation and your needs, engineer an optimal technical solution with highest usability, design optimal set of EnPIs and KPIs to follow, ensure short delivery and implementation period for EnMS hardware and software components, with an adequate and precisely-defined quote, without any hidden costs for maintenance and software updates.

Our most important references in Energy Mangement system projects (EnMS):

- HBIS Steel Mill Smederevo

- USCE Shopping Mall

- Copper mill Sevojno

- Cardboard factory Umka

- Paper factory Drenik Beograd

- Tetrapak Gornji Milanovac

- Alfaplam Vranje

- Galenika Fitofarmacija

- Motoplast Stara Pazova

- Brewery Efes Vajfert Pančevo

- Brewery Zrenjanin